|

d) Commercial sisal fibre extraction

e) Extract your own sisal fibre

f) Uses of sisal fibre

g) History of sisal fibre

h) Environmental benefits of sisal fibre

d) Commercial Sisal Fibre Extraction

The fibre must be extracted as soon as possible after the leaf has been cut; if the leaf is allowed to dry, the fibre is easily damaged during the cleaning process. To extract the fibre, the leaves need to be crushed and the fleshy pulp scraped away, a process called decortication. After this the long fibre needs to be cleaned. The fibre must be extracted as soon as possible after the leaf has been cut; if the leaf is allowed to dry, the fibre is easily damaged during the cleaning process. To extract the fibre, the leaves need to be crushed and the fleshy pulp scraped away, a process called decortication. After this the long fibre needs to be cleaned.

In East Africa, the decortication is done in factories; the leaves are crushed between rollers and then beaten by a rotating wheel with blunt knives. Water is used to clean the fibre which is then hang on lines to dry. In Brazil, smallholders use a portable machine called a ‘raspador’ and instead of using water to clean the fibre, the fibre is brushed clean.

e) Extract your own Sisal Fibre

If you want to process your own fibre from species of agave, you need to be very careful of the sharp points and wear eye protection and strong gloves when harvesting the leaves. I also strongly recommend wearing rubber gloves when scraping the leaves as the sap can cause a serious skin rash (dermatitis). Cut only one leaf and process it straight away before cutting the next leaf. Find a smooth stone that fits nicely in your hand and beat the fleshy leaf. Alternatively you can use a wooden mallet instead of a stone to crush the leaf.

Then use a blunt knife (e.g. an old butter knife) to scrape the flesh away. Start scrapping near the tip of the leaf and gradually move along the length of the leaf. If beating sounds too much like hard work, you can ret the leaf in warm water for a week or two before scraping the fibre. However this can be a smelly process and the fibre will be grey in colour.

You can use a similar decortication process to extract fibre from sanseveria (mother in law's tongue), pineapple and New Zealand flax (Phormium) leaves.

f) Uses of sisal fibre

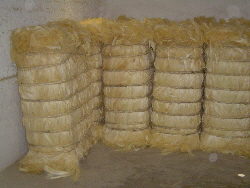

High grade sisal fibres are long and are made into yarns (either on their own or in blends with wool or acrylic) and used in carpets. Medium grade fibres are made into cordage, ropes and twine, for agricultural and industrial use; they are particular useful in a marine environment as they are resistant to deterioration by salt water. Low grade shorter fibres are valued in the paper industry because of the high content of cellulose and hemicellulose; they help to strengthen recycled paper.

One of the traditional uses for sisal is baler twine, as the fibre is long lasting and flexible. This use, however, has greatly decreased as the twine is being replaced by polypropylene and at the same time new harvesting technology uses much less twine. Sisal is still the best material for making dartboards.

Sisal is being used in composites instead of fibreglass to reinforce components if the automotive and aircraft industry. Sisal is also being used in the construction industry as cement reinforcement for low cost housing, as plaster reinforcement and for roofing materials, as well as insulation. Sisal is also great as a buffing cloth as it is strong enough to polish steel, and soft enough not to scratch it. Another use for sisal is as a geotextile in land reclamation, stabilisation of slopes and road construction. It also makes good cat scratching posts.

g) Sisal fibre history

Sisal has been made into cordage since pre-history, and then made into bags, netting and clothes. The sharp and strong leaf tip has been used as a needle, with the fibre still attached to it. When the fibre ran out more could be attached through splicing.

The name sisal comes from a seaport town in the Yucatan peninsula of Mexico. This was the principal port of Yucatan during the henequen boom and sisal fibre was shipped through it. In fact up to the beginning of the 20th century sisal was cultivated mainly in Mexico.

In the late 1930’s, commercial plantations started in Brazil, and today Brazil is the major world producer of sisal. Tanzania and Kenya are also important sisal producers. In East Africa most of the sisal is grown in large plantations and exported, while in Brazil it is mainly grown by smallholders and used inside the country.

Although traditional uses of sisal are in marked decline, there is renewed interest in this fibre as a composite in the automotive industry, to reinforce building materials and for geotextiles. Sisal is also gaining popularity as a natural fibre for interior design.

h) Environmental Benefits of Sisal

Unlike synthetic fibres, sisal is 100% biodegradable during its lifetime, and sisal strings and ropes can be recycled as paper. During processing sisal produces only organic wastes, which can often be reused. In the past, 96% of the leaf weight was discarded. Now this is used as fertiliser, cattle feed and as fuel for biogas production.

The plants can be also used as an effective hedge to protect crops and land from predators, and the extensive root system helps to reduce soil erosion in arid areas.

Back to:

a) Biology of sisal (opens new page)

b) Sisal fibre (opens new page)

c) Cultivation and harvest of sisal (opens new page)

Top of page

|